Why are more and more spring manufacturers choosing Xinding

Machinery?

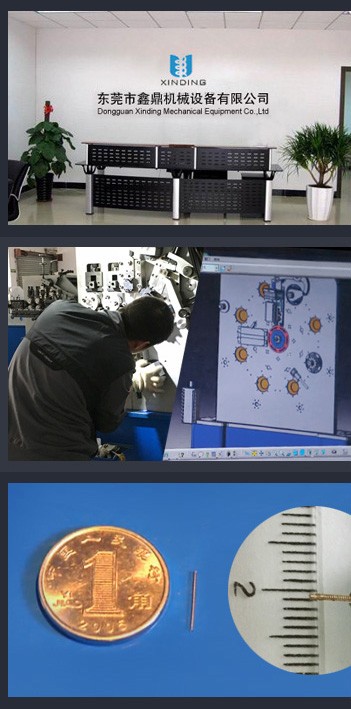

Dongguan Xinding Mechanical Equipment Co.,Ltd is

specialized in CNC spring machine for over 20 years, and has

gradully grown with the trust and support of its loyal client base.

With years of development, the company has managed to

accumulate a great amount of experience in production technology

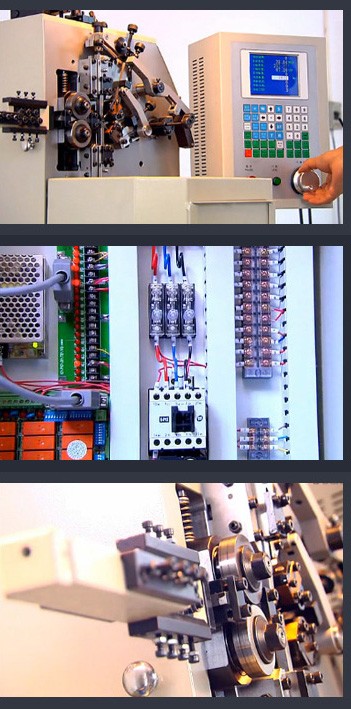

and is now able to offer high speed and high precision spring

making machines that are durable, practical, and easy to

operate.

Users will be able to operate our spring making machine in

no time and our machinery will improve your production efficiency

by reducing time wasted performing repeated actions. In

addition, our company owns independent R&D and design capacity

and is able to manufacture machines according to customer's

inquirement.

So far, our company has served thousands of spring

manufacturing enterprises and has won their high praise and

recognition. At the same time our products not only meet the needs

of domestic users, but also sell well in many countries and regions

overseas. Our products have been sold to overseas countries, such

as America, England, France, Germany, Canada, Russia, Korea,

Singapore, Malaysia, Thailand, India, Vietnam, Indonesia,

Philippine, Iran, Turkey, Bulgaria, Mexico, Peru, Poland, Belarus,

Brazil, Argentia, Pakistan and so on while have received a

lot of good comments.

We insist on the concept of "Quality Priority, Customer First, Keeping Improving" . We firmly

believe that the products stand up to any practice and sincerely

wish to establish long-time business relationship with esteemed

customers of all over the world. If the company's philosophy and

products are just what you have been looking for, please do not

hestate to contact us.

● Our Products

Our spring making machines cover spring wire diameter from

0.15mm to 8.0mm, including:

◇ CNC spring coiling machines: XD-208, XD-212,

XD-220, XD-230, XD-330, XD-240, XD-340, XD-250 and

XD-350 series.

◇ Multi-axis spring coiling machines: XD-608, XD-620, XD-630, XD-660,

XD-680, XD-808, XD-820 and XD-830 series.

◇ CNC universal spring machines: XD-CNC20, XD-CNC35, XD-CNC0520 and

XD-CNC0535 series.

◇ Camless CNC spring Forming machines: XD-CNC1020,

XD-CNC1120, XD-CNC1245, XD-CNC1260 and XD-CNC1280 series.

Besides, various types of peripheral equipment such as wire forming

machines, tempering furnaces and spring grinders, as well as

computer controllers, inspectors and spring machine mold

accessories.

● Why choose to us

◇ Over 20 years of experience in manufacturing spring

machinery.

◇ All machines recieve a lot of

good comments from customer.

◇ Independent R&D and design ability to support of products.

◇ Always happy to serve and work with our customers

from all over the world.

● Contact us